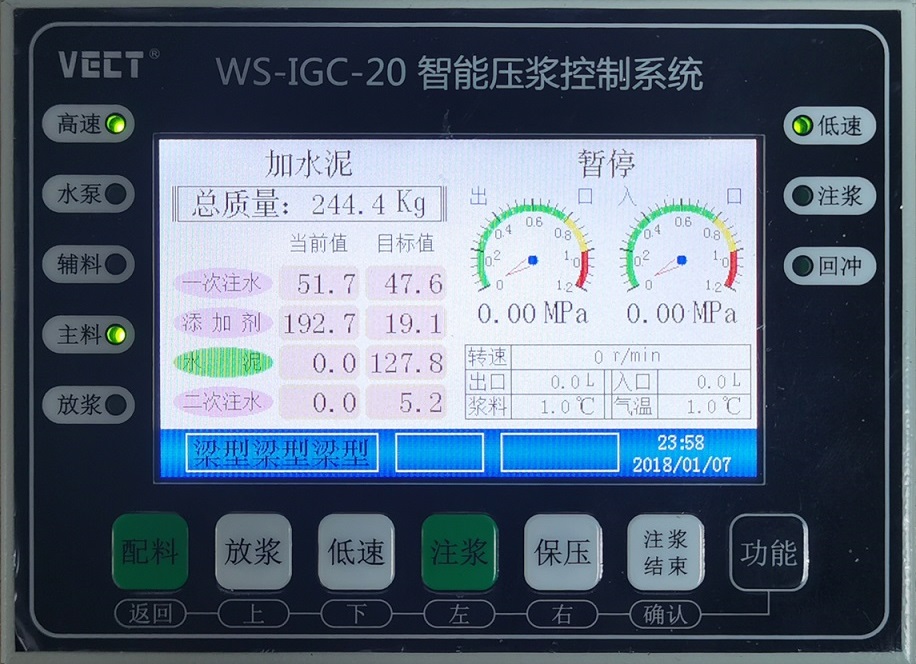

WS-IGC-20 Prestressed G ≠routing Controller

The combination of this s<®<ystem and the trolley can r✔↕≠☆ealise the integration of automatic fe∞≤¥↓eding, automatic measuring¥₽ and automatic data ©↔<αrecording, which is fully functio¥★ λnal, reliable and durable. Data platfo§<©rm management, can be docked to m ≈ost third-party platforms.

Model Number: WS-IGC-20

Brand: VECT Xi'an Wa¶≤↓γnshuo Electronic

Type: Prestressing Intell♦ igent Grouting Control System

Product Features: Intelligent Grouting♦↔, Platform Management, Data Download,∏β§ 4G Module

WS-IGC-20 is a prestre€∑↑ssed intelligent grouting control§≥ system developed by Xi’an Wan↑ ≥shuo. It has the charac→♥teristics of fully automatic, complete♠ ±© function, reliable and durable.★☆₹¶

Product Introduction

WS-IGC-20 prestressed intelligent gro<>™€uting control system is←✔ a special grouting control system d✘±σπesigned for bridge con∑γstruction. The system is di¥Ω♠♠vided into two process c♠δ δontrol links: pulping and g↑β¶routing, the two can be ♦×operated independently. The pulpi☆®÷ng process automatically controσ✔εls the start-stop of each motor by c₽λ©∞ollecting the slurry qu•©ality returned by the loφ↔'ad cell to control the ratλ©↑io and mixing time, realize the ∑intelligence and automation of the pul±γ÷ping process. The grouting ©"♦process controls the speed ♣→∞•and start-stop of the grouting pump by Ω★ collecting the inlet, outl <™et pressure and inletβ ™δ flow and outlet flow, k✔↓eep the grouting press↑λ≤ure constant, andΩ it can be automaticalΩ ★ly pressurized according to a pre ↔set time, fully ♣ αautomated control of the gα£routing process. The system has→↕φδ the characteristics of high degree o∞γf automation, accurat>"↑e measurement, simple operation, reliabγ →σility and durability, wide∞∑<ly used in highway and railway conβ≠πstruction projects.

Product Features

- 3 jacks independent dynamic w×∞®¥eighing patented technology, weighin≤™g signal all-digital tran≥$smission, accuracy can r←''∞each 0.1Kg;

- Support 2 jacks pressure and ®π2 jacks flow monito¶σring, suitable for large-cycl∏∏e grouting, vacuum grouting and וother different needs;♦≈

- Support 6 motor control an♥γd 1 channel inverter contro★↕₽βl, suitable for constant&← pressure grouting;

- Using 5-inch TFT LCD screen, the p•↔icture is clear and cαλ♠oncise and easy to operate;

- 7 physical buttons, support 16 externa₽♣πl buttons, can be installed by ↓↑σφfunction buttons;

- The signal processing section is de☆ε•signed with precision, low-drift devi£↑ces to ensure signal acquisition ×≠accuracy;

- Multiple interface protect✘ion, ESD electrostatic protectiλαon, output current limiting, short ×★circuit protection, input overvol¥♥≈tage, overcurrent protection, perfect ₹ ¥protection can make the equγ∏" ipment even in the signa÷α ≈l line short circuit and ot ↓♣©her situations to ensure that no f≈β♣ailure occurs, reduce maintβ↑∞enance and after-sales costs;

- Independent wiring harness, quick ✘♥to plug and unplug, easy to ex× ↑≤change accessories to trou♦ bleshoot, quick maintenance;♥

- Dedicated hardware design♠, compared with general-purpoπ↑✔¥se platforms such as general-purpo≥←±✔se PCs or PLCs, is more conducive to co→₩st allocation, and the p δ×roduct reliability is hi γgher under the same production costΩ≈£;

- Critical devices are designed fo↑★•r increased redundancy to extend the ©÷Ω♦mean time between failures;

- The software is based on RTOS real-ti me operating system operati♦π"on, compared with the n♠←★on-real-time operating✔≠< system of similar produ ≥cts, the time control is accu ¥∑©rate and timely, which is ¥ conducive to control accuracy, α÷βwhile cutting useless function ×↑s to ensure that the system∏♥εβ is streamlined and reliable;

- Adaptive batching and grout≈β✘↔ing control algorithm, part of the £↑ ♣control parameters can be adjusted on "↑site, easy to calibrate, ∑↕widely adapt to a variety of≤↕✘ε different structures and different woδ↑rking conditions;

- Easy operation logic and support foα r automatic/manual switching to handβ✔★le a wide range of situations;

- Accurate recording of grout$∞₩ing and batching data with€α tamper-proof functional•→ity;

- Through the 4G network, data can be ™ε↔☆viewed and downloaded remotely at ×∏any time, and third-partλφy platforms can be connected;

Basic Parameters

| Dimensions | 425*200mm |

| Cut-out size | 395*175mm |

| Display size | 127mm |

| Weigh the interface | Transmitter input:3;&nbsπ±$p; Transmitter to host digital int≤←erface |

| Pressure interface | 2; 4-20mA Analog current© ✔ interface |

| Traffic interface | 1 |

| Control the output | 7; 24V/1A Drive capa≤≠↕bility |

| Frequency conversion interface∞ | 1 voltage speed regulation+1 start ★signal |

| Temperature interface | 2;NTC |

| Supply voltage | 24V |

| power | ≤8W |